Introduction

At week 9, the study focused on a literature review of existing projects that have been in the market. This study is important, to ensure that project will be built on the right track, so that, it does not depart from the original objectives of the project. Results from this study will be used to improve project microcontroller-based egg incubator, in order to complete a project eggs incubator better than before.

Objective

- To gather information from the existing project as a reference.

- To study about eggs incubator control system using microcontroller and other devices.

Project Encountered

This week, more study on literature reviews as reference material and to add the idea in designing the project. Actually, none of the problems encountered in this review, because it is just knowledge / guidance in developing an incubator project, so do not much of a problem encountered during the completion of microcontroller based projects egg incubator

Project Description

There are many egg incubators at market nowadays. They come with several features that differentiate their product with other. However, they use the same principle in creating their product. For example, Automatic Forced-Air Incubator uses a light bulb to increase the temperature in the incubator, while, Mini Eco Eggs Incubator , uses heater coil for the same purpose. In this project, smart incubator makes the other eggs incubator as literature review in order to provide an automatic eggs incubator at low cost and easy to handle.

Below is 2 example existing project to be the reference :-

- Automatic Forced-Air Incubator

Automatic model with a capacity / load the eggs of 100 eggs, also can accommodate nearly 300 quail eggs. For operating an automatically diverting eggs for up to 8 times a day by the installation of electric motor, timers and relays. Using a thermostat brand products Caemz Italy known for its precision control of temperature up to 1 degree Celsius, clear digital thermometer displays the temperature of incubator operation, the blower fan is temperature resistant and moisture and heat lamps are easily replaced with 5 watt, low and save electricity.

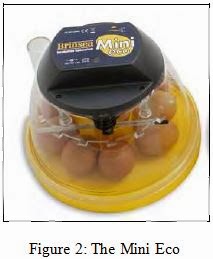

- The Mini Eco

The Mini Eco holds 10 hens‟ eggs (or equivalent) and provides the fine temperature control to ensure consistent and reliable hatches. Temperature is monitored on a purpose built liquid-in-glass thermometer and although factory set, the electronic temperature control allows fine tuning of the temperature setting if required.

Based on studies and observations that have been performed on two example project that Automatic Forced-Air Incubator and The Mini Eco. There are some advantages and disadvantages on both of this project. Therefore, all the advantages of existing projects will be used and any deficiencies will be corrected/improved. Below, there is little information about the features of the project to be developed and the project is already available in the market today.

No comments:

Post a Comment